Die Cutting Products

Adhesive control is NOW in the hands of the Converters!

Shop Coatings for Die Cutting

The Best Non-Stick Coating Solution for Controlling Adhesive Buildup in Printing & Die Cutting…Period.

Whenever you proclaim something as the “BEST”, your credibility had better be ready to be challenged. To start, Dyna-Tek isn’t new to the Die-Cutting industry. The potential of our coatings was first recognized by PRECO in 2017. They were enamored with its potential enough to enter into a private label agreement to sell our coatings under the brand names of Die-Slide™ and Die-Slide™ Renovate.

Once the term of this agreement came to an end, we opted to take over the sales and distribution ourselves. Today the Die Slide™ is Dyna-SlickShield™ and Die-Slide™ Renovate is Dyna-SLICK™ PLUS .

Eliminate Adhesive Buildup

The keys to mitigating adhesive buildup starts with:- Sealing the porosity of the surface it is applied to. Dyna-SlickShield™, as its name implies, serves as the “shield” for the surface where it not only seals off the porosity with its dense and durable molecular coating structure, but as its name also implies, it results in a hydrophobic surface as well.

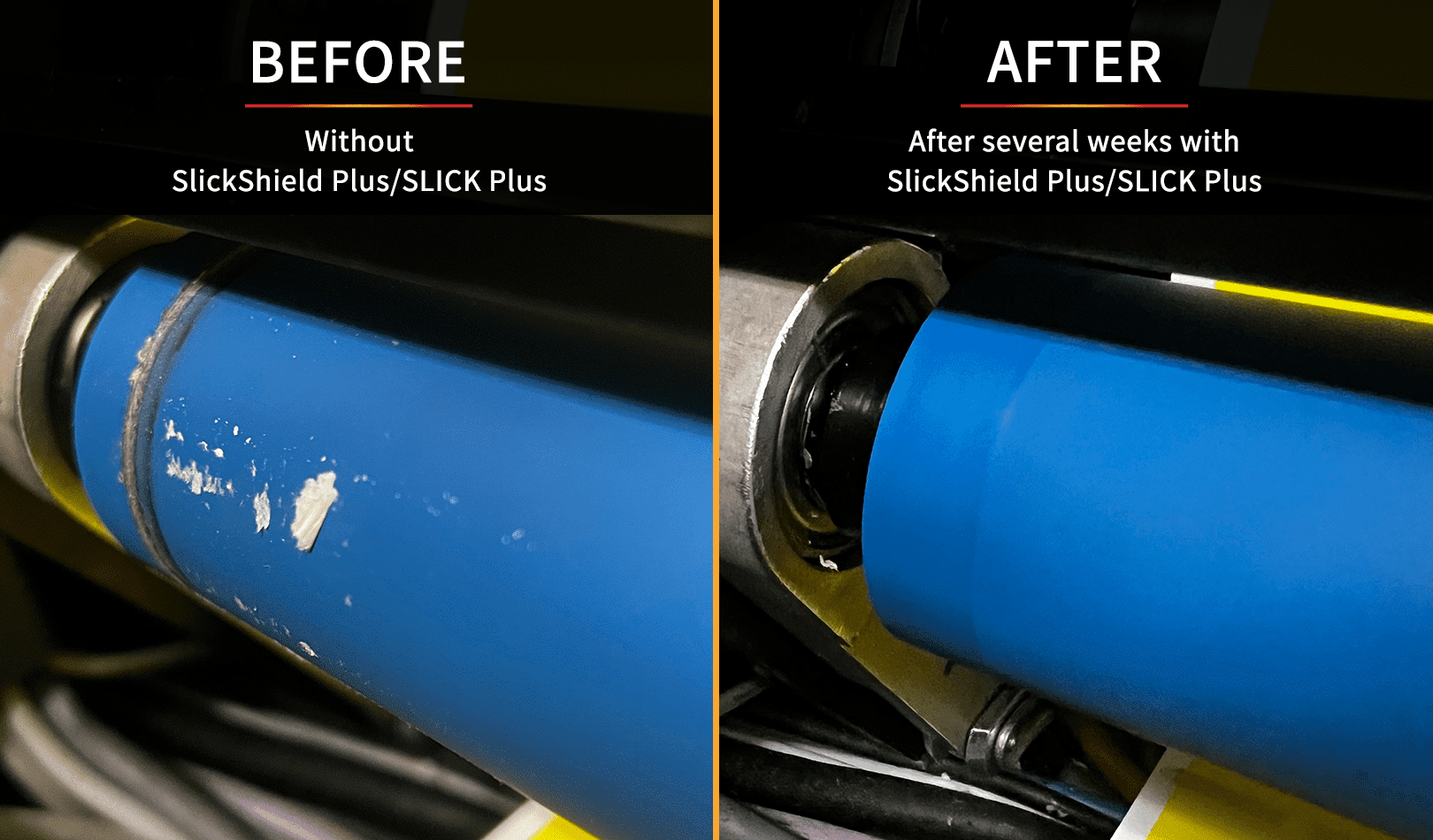

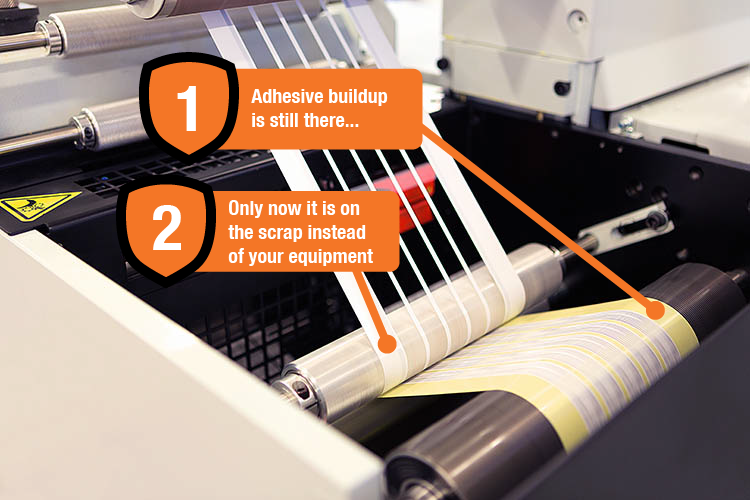

- A Superhydrophobic finish ensures the elimination of adhesive buildup. This is where Dyna-Slick™ Plus excels. By itself, Dyna-Slick Plus isn’t thick enough for its release properties to be optimized, but the combination of SlickShield and Slick Plus will ensure that adhesive buildup is left on the matrix... instead of the dies, rollers and other components.

Non-stick Results that keep on giving

- The performance of ALL non-stick finishes diminish due to operational wear and tear... and usually well before the cutting surfaces lose their edge. This results in more aggressive cleaning efforts, which ultimately causes additional wear to the dies and rollers, causing their operational life to decline faster.

- A big reason why Dyna-Tek's products are the best is because they can be recoated at the Converter’s plant, by the Converter’s team. When you see signs of adhesive residue starting up, clean it with Dyna-Prep, and add another coat of Dyna-Slick Plus.

On-site (DIY): Easy Application By the Converter

- Easy to apply. Wipe-on or spray application to the areas you want to keep clean and adhesive free

- No shipping dies out due to sticking issues

- Ambiently (air) cures in 60-90 minutes and can be put back into operation... sometimes without removing the components from the equipment

Safety: Reduces Static Build-up

- Dyna-SlickShield Plus is inherently non-conductive

- Our coatings reduce the friction occurring at the rollers which minimizes static buildup

- No more Taser hits!

Improve Profitability

- Minimize production stoppages due to adhesive buildup – on all adhesive types

- Less downtime, more production time and throughput - Press runs longer

- Reduce quality issues related to adhesive build-up on dies that causes missing labels, which decreases blocking during rewind.

- Dies last longer - less wear and damage

- Significant reduction in labor time (costs) spent cleaning, repairing, and maintaining equipment dies, rollers and other components impacted by adhesive build-up

- Allows you to run production time longer vs. shutting down sooner to account for the longer time usually needed to clean at the end of a shift

Advantages Dyna-Tek has over competitors

- Temperature resistance up to 750° F/399° C

- Hydrophobic properties equal to, and better than fluoropolymers

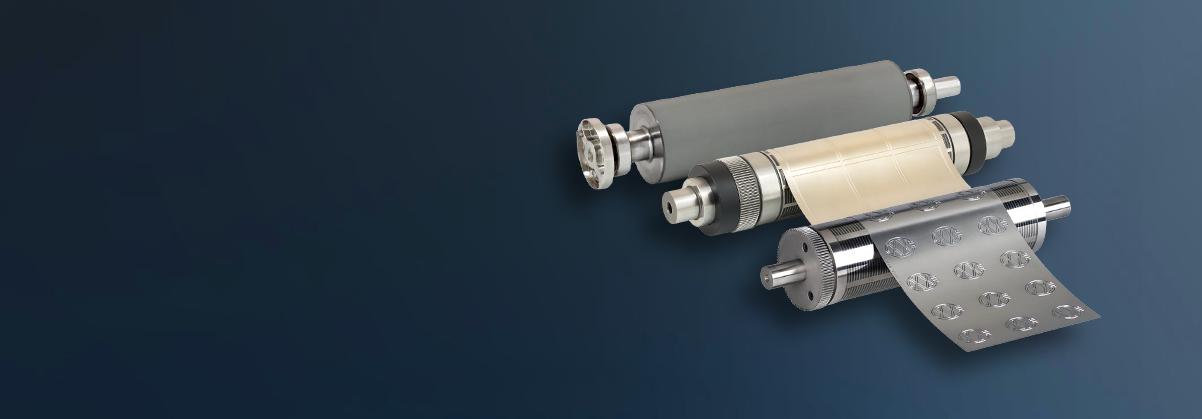

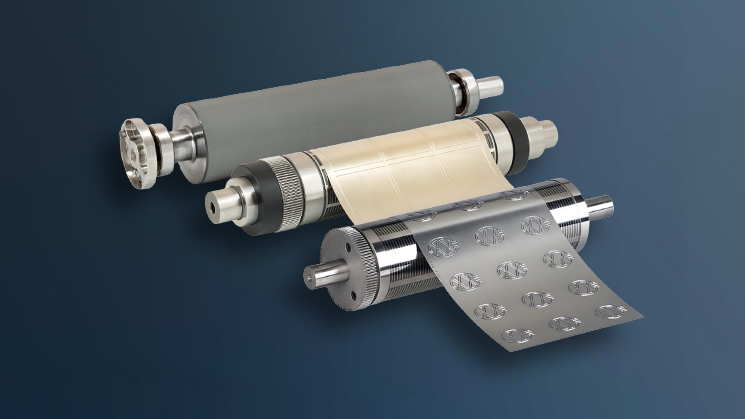

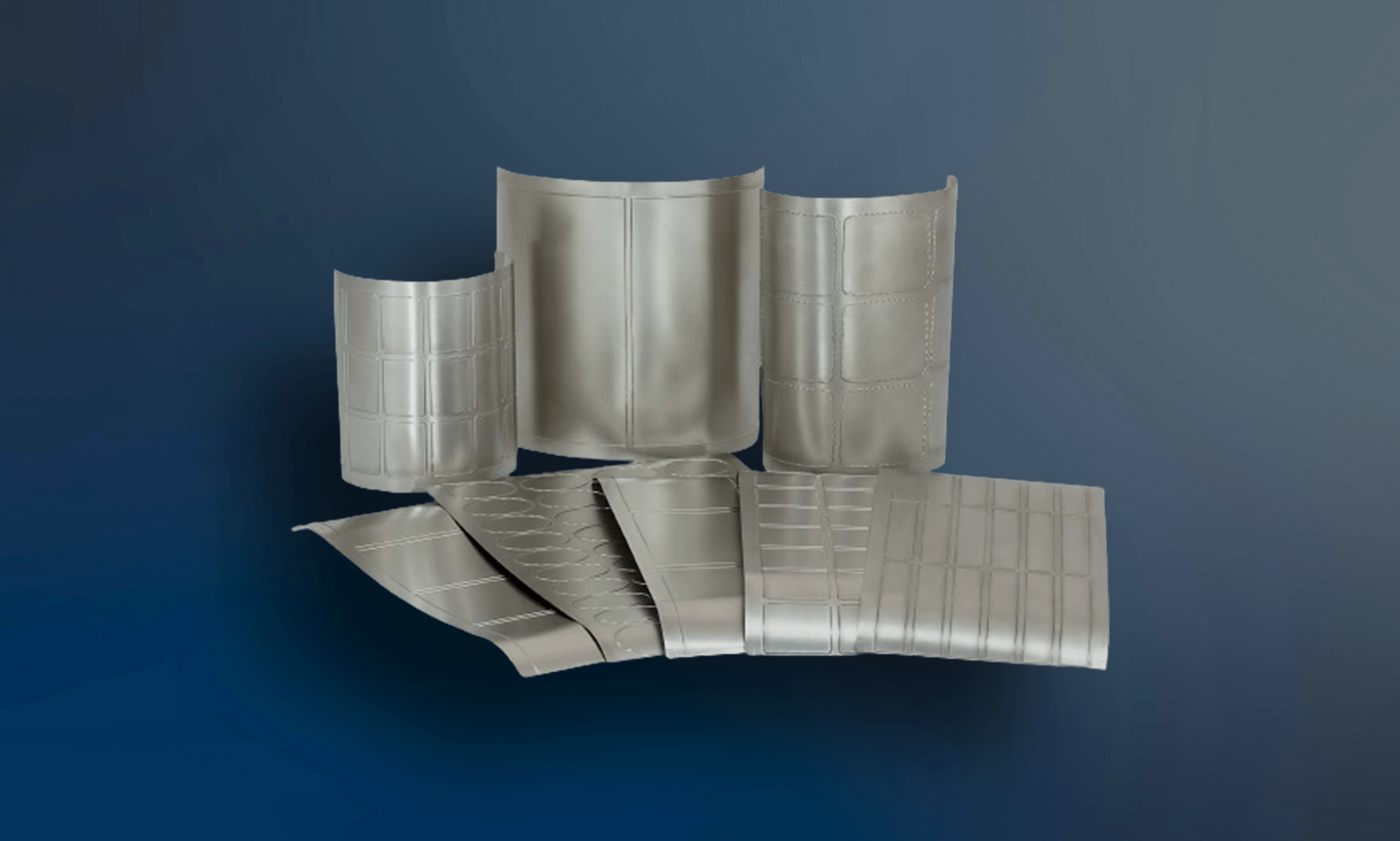

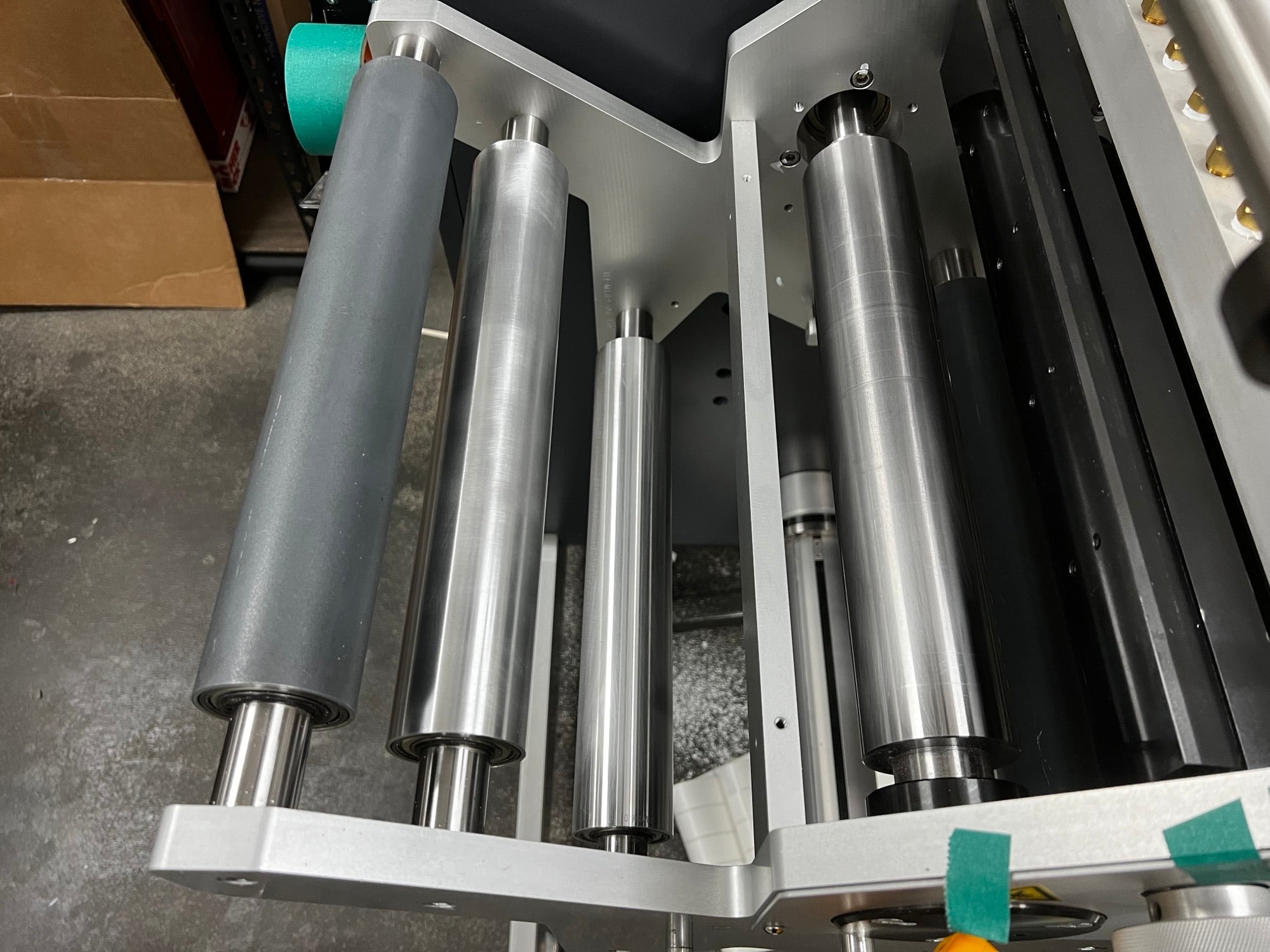

- Coatings can be used on Dies, Rollers, Slitting blades, cutting wheels, knife blades

- Non-stick properties can be refreshed by the converter

- Tooling does not leave the converters possession

- Cost effective

Shop

Smooth Dies & Rollers

If your die or roller is very smooth and polished then we recommend the SlickShield Starter Pack.

Textured Dies & Rollers

If your die or roller has a lot of high/low points or is porous and/or textured then we recommend the SlickShield Plus Starter Pack.